The industrial scaling of cultivated meat faces a key challenge: the economical production of tasty and nutritious cell mass, particularly in terms of quantity and quality. CellTec Systems is now presenting research results that point to new approaches. By exploiting the natural plasticity of primary cells, it is possible to produce both the nutritional profile and the flavor-giving fat components efficiently and without genetic modification, the company states.

Muscle Similarity Without Differentiation

“A decisive time and cost factor in bioprocess engineering is the differentiation of stem cells into specialized muscle tissue. However, in a collaboration with the Institute of Medical and Marine Biotechnology (IMMB) at the University of Lübeck, CellTec Systems has demonstrated that primary cells obtained from a simple skin punch biopsy already exhibit a remarkable biochemical similarity to muscle tissue in their undifferentiated state. Chromatographic analysis of the amino acid composition reveals that the profile of these cells—unlike conventional fat or skin tissue, where glycine dominates—contains high levels of glutamic acid, lysine, and leucine. These amino acids are typical markers for protein-rich, metabolically active tissues. Consequently, even in their undifferentiated stage, these cells possess a nutritional profile at the molecular level that is nearly equivalent to high-quality muscle tissue. This makes elaborate differentiation optional for achieving biological value,” the company stated in its latest press release.

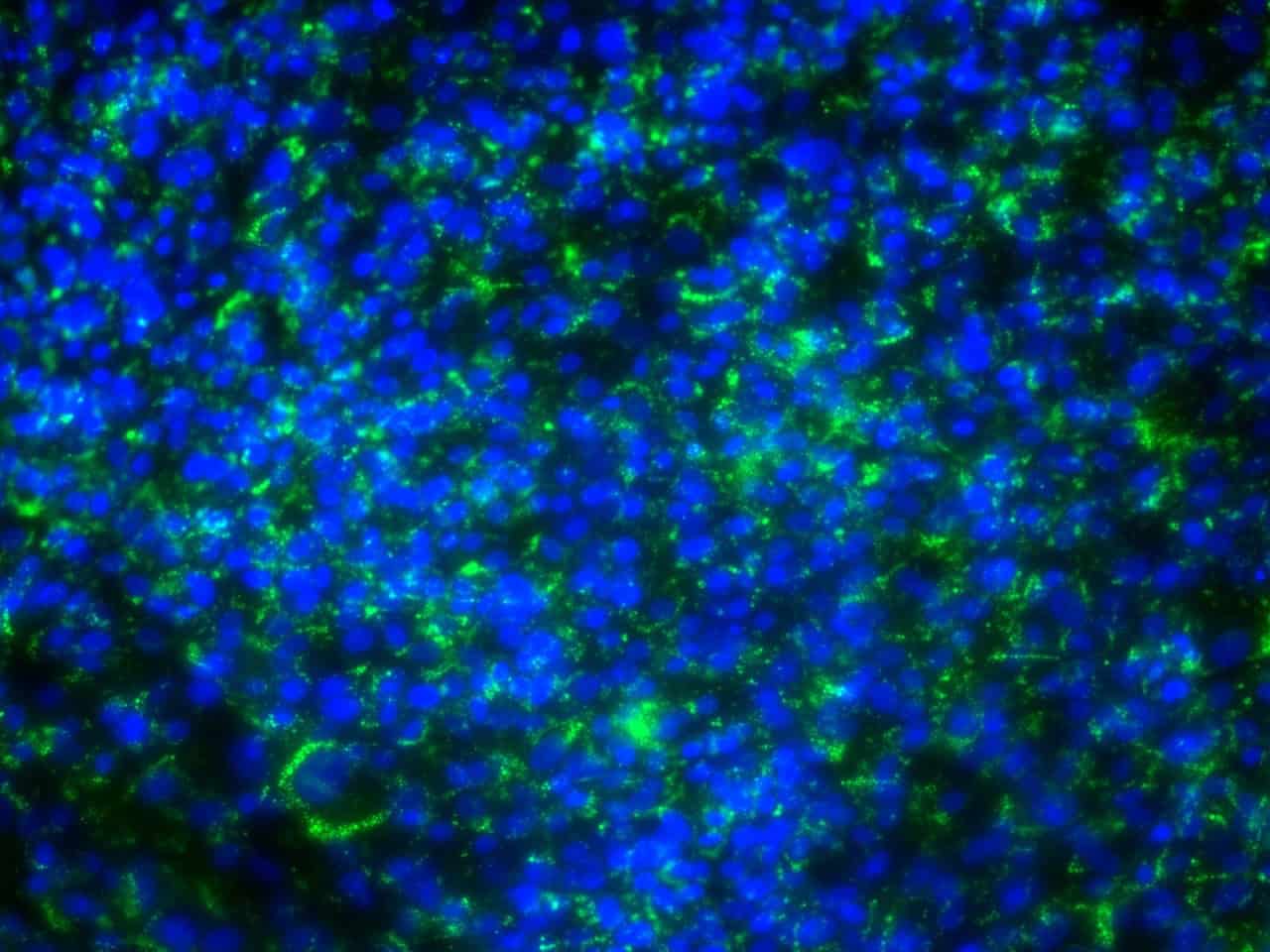

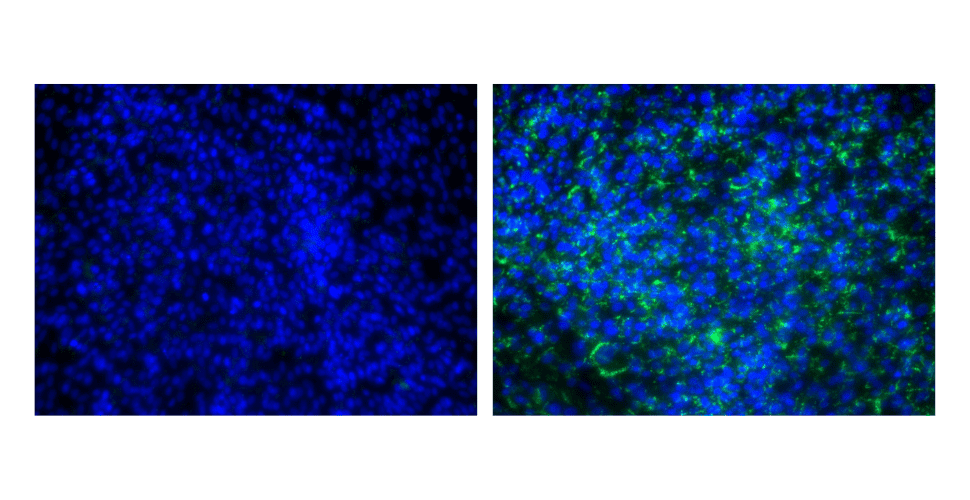

Fluorescence images of bovine cells under normal culture conditions (left) and after adipogenic differentiation (right). Intracellular lipid droplets were stained green (BODIPY) and cell nuclei blue (DAPI). © CellTec Systems

Fluorescence images of bovine cells under normal culture conditions (left) and after adipogenic differentiation (right). Intracellular lipid droplets were stained green (BODIPY) and cell nuclei blue (DAPI). © CellTec Systems

Targeted Fat Differentiation for Authentic Flavor

Furthermore, the company states that parallel to the protein base, CellTec Systems has demonstrated that these same long-lived cell strains can also be differentiated into fat precursor cells. Through targeted nutrient supply, the cells accumulate lipid droplets in visibly significant quantities.

These results are said to be of great importance to the food industry because the cells significantly contribute to flavor, even without extensive differentiation. This enables an authentic taste experience while ensuring the production process remains entirely free of genome-editing techniques. As a result, both regulatory hurdles and technological complexity are reduced, shortening the time to market. Additionally, the primary cells used are characterized by a high division rate and stable proliferation, further underscoring their suitability for reproducible and prospectively scalable processes.

Economic Viability from Biopsy to Scalable Process

“Our results prove that we can produce cells with the properties of real meat without any detours,” says Dr. Teresa Buck, Head of Cell Innovations at CellTec Systems, describing the advantages. “By dispensing with genetic interventions, we not only eliminate regulatory hurdles but also reduce technological complexity. The combination of genetically unmodified cells with high proliferation potential, a natural similarity to muscle tissue, and the ability for targeted fat storage makes the process economically scalable and represents another milestone on the path to marketable cultivated meat.”